British-born engineer Elihu Thomson discovered that copper could be fused together in 1876, but it was not until 1885 that a method for resistance welding was proposed. Direct energy spot welding is a resistance welding process that combines metals by applying pressure while supplying electric current to the weld area.

Resistance spot welding has evolved into a fast and cost-efficient welding process extensively employed in sheet metal manufacturing. The automotive sector has benefited from this technique by utilizing robot spot welders, facilitating increased production and assembly speeds. While primarily used for welding steel, there is a growing trend towards the substitution of steel with aluminum to achieve mass optimization over time, and the market is estimated to be worth almost $500M by 2031.

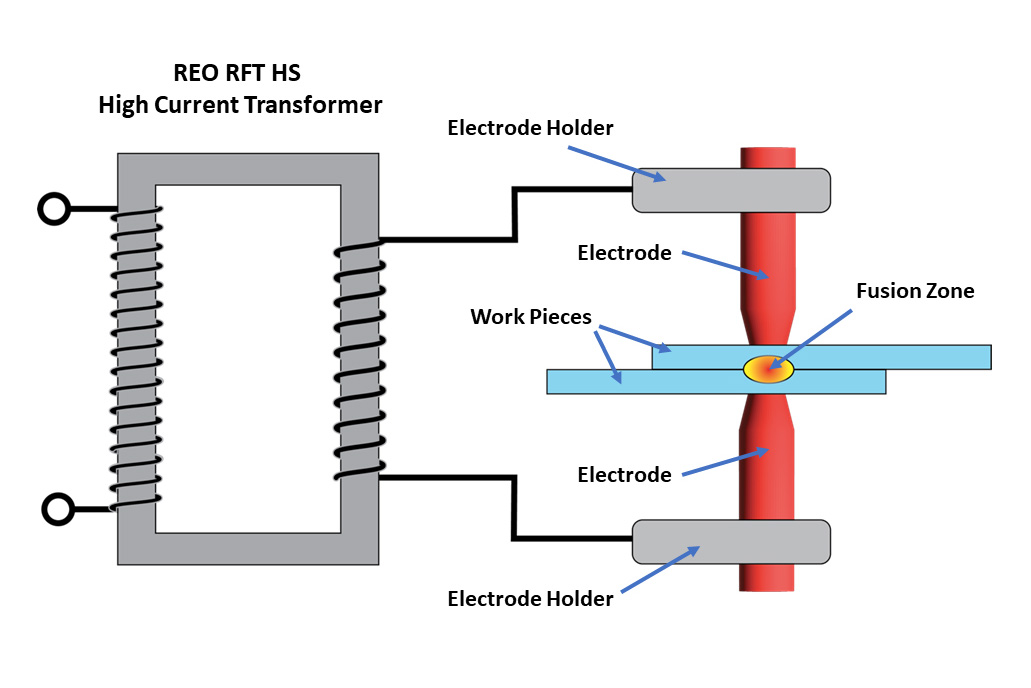

Welding Power Supply

Spot welders usually use an AC supply voltage. The power source and equipment used for this type of welding must be carefully controlled to ensure precise and reliable welding results.The specific power rating for a given welding application is determined through process development and optimization based on the material characteristics, desired weld quality, material thickness, and speed requirements, and at the heart of the Welding Power Supply is a high-current isolation transformer, rated for the maximum power and duty that can be expected for the application. REO’s RFT-HS toroidal transformers use multiple toroidal cores to achieve the power requirement; the units have a standard wired input and use copper bus-bar to form the secondary.

The toroidal design can be up to 40% more efficient than conventional EI-type transformers, an essential consideration in price-sensitive applications. REO’s range of Toroidal Transformers have other benefits, too; they can be encapsulated to provide ingress protection (IP) to up to IP54, and the center point fixing method means that they are quickly mounted within equipment or control cabinets, saving time, and yet more money. They are specifically designed to outperform standard EI transformers, providing better load regulation, lower levels of leakage current, and lower losses.

Applications of Spot Welding

Automotive Industry

As mentioned above, spot welding is a critical element of the automotive industry since it is cost-efficient, reliable, and fast. Manufacturing companies can easily automate assembly lines by using spot welding robots. A metal sheet or pressed panel made from steel or aluminum can easily be transformed into a functional part in seconds.

Electronics

Because this welding method prevents overheating of the electronic components, many components such as switches, potentiometers, relays, printed circuit boards, and batteries are well-suited for spot welding.

Nail Manufacturing

It uses a high-speed, continuous spot welding process, which converts carbon steel rolls into nails at thousands per minute.

Kitchenware

Spot welding is often used to form door and cupboard handles, spatulas, and certain types of kitchenware, like biscuit cutters.

Medical Industry

The medical industry also benefits from this process’s welding quality and speed. For instance, orthodontics utilizes spot welding to fasten dental implants securely.

Advantages of Spot Welding

- Spot welding is considered one of the fastest and cleanest welding methods.

- Easy to understand process.

- No open flame is present, unlike other processes, such as arc or TIG welding.

- The process can be easily automated.

- Multiple workpieces can be joined at the same time.

- No need to use filler rods

- There is no requirement for the use of inert gases

Disadvantages of Spot Welding

- Workpiece alignment and pressure are critical.

- Spot welding can cause deformation in some regions of the base metals.

- It is generally not possible to weld material thicknesses >3mm.

- The joints created may be weaker than with some other welding methods.

- Weld current can be diverted (Shunted) from the electrodes to other welds on the workpiece, resulting in poor weld performance.

As the drive continues to optimize production techniques, especially in light of the increased use of aluminum in automotive and aircraft production, making products lighter and more fuel-efficient, resistance welding will likely remain an essential manufacturing process for many years.